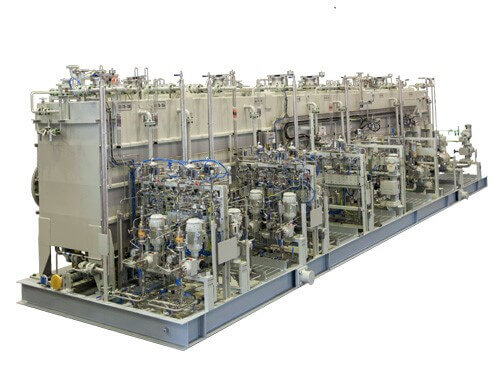

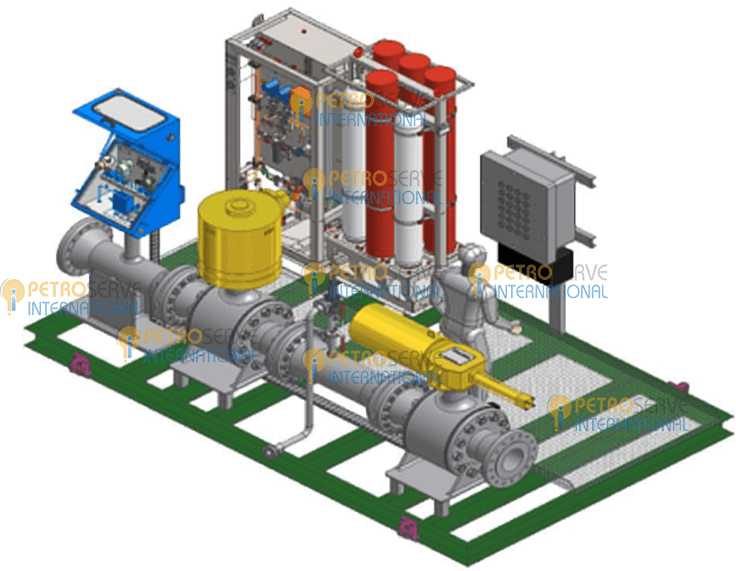

A High-Integrity Pressure Protection System (HIPS) is a type of safety instrumented system (SIS) designed to prevent over-pressurization of a plant, such as gas, chemical plants or oil refineries. The HIPS acts as a barrier between a high-pressure and a low-pressure section of an installation, shutting off the source of the high pressure before to exceed the design pressure of the system, thus preventing loss of containment through rupture (explosion) of the line or vessel.

HIPS consists of sensors, logic solvers, and final control elements used to prevent over-pressurization and loss of containment on process and equipment by shutting off the source of high pressure before exceeding the process design pressure. A HIPS system is designed as an independent and separate safety protection layer separate from the Emergency Shutdown System (ESD). HIPS are independent and reliable systems that shall operate on a higher Safety Integrity Level (SIL 3) than Process Shut Down and Emergency Shut Down (ESD).

A HIPS system must be in compliance throughout the systems lifecycle to the strict conditions of approval resulting from a quantitative risk assessment, dynamic process simulations and other specific design considerations.

PSI is able to supply the HIPS system as an integrator.