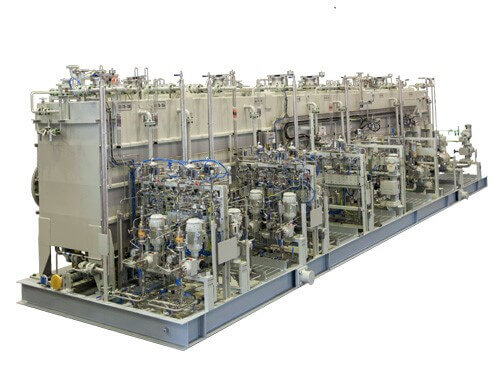

Chemical Injection Skids (CIS) is an integrated system used to dose and inject various chemicals into different pipelines at various conditions. In the Oil and Gas industry this helps to increase production, reduce corrosion and to improve the process. High level of accuracy is required for dosing system because of the environmental and financial reasons. Based on the flow/pressure requirements and various chemicals used, the metallurgy and the design of the skid changes.

It is basically composed by different components such as, Chemical Injection Pumps (API 675), Chemical Storage Tanks, Safety Valves (API 520/526), Isolation Valves, Instruments, Piping & Structural frames.

Pumps:

Pumps are the fundamental aspect of chemical injection systems because they provide the source for generating the flow and the pressure required to achieve the system’s objective. Pumps may be of a diaphragm or plunger type. It can be designed to operate in different power sources viz electric motor, air operated, solar powered or solenoid driven motor.

Tanks:

Tanks are one of the most fundamental aspects of any chemical injection system because they required to store the chemicals which need to be injected into the system. Tank size and structure may vary, but typically they will be horizontal and cylindrical. They may feature a flat, conical, or dished bottom with a flat or dished top.

Suction/Discharge Piping & Valves:

In order to carry the specialty chemical from the storage tank to the dosing pump, suction piping and manual valves are installed on the chemical injection package. Discharge piping and manual valves carry the high-pressure chemical from the dosing pump to the skid edge, where the chemicals are routed to their final injection point. Mechanical isolation valves, check valves, calibration columns, etc. are all a part of the overall chemical injection package.

Instruments:

Instruments are needed to measure and monitor the system continuously. For instance, they will often monitor the chemical level inside the tank, allow for the calibration of the flow rate, monitor and adjust the pressure within the system, and set off alarms and other fail safes designed to ensure safety and proper function. Specific gauges and valves may vary depending on the exact purpose of the chemical injection system and the client’s own unique set of requirements and needs.

Skid Structure:

All skid mounted chemical injection system feature a skid structure as part of their fundamental component parts. The skid structure provides the structure itself for the system and is designed in such a way to protect the system while accommodating its various parts. It usually features structural steel which has been continuously welded. Often it will also feature a drip pan designed to collect drained chemicals and to protect environment.

Features of the skids:

Skid is designed with pump protection device and associated interlocks to avoid dry runs.

In-house manufacturing (i.e., fabrication, assembly, system integration and testing facility) of the skid on a single frame makes it ready to use at site and ensures minimum site work.

In-tank mixing facility can be provided as required with motor driven agitator.

Manual or automatic stroke adjustment for the pumps can be provided.

Commissioning & Maintenance.

Our highly skilled service engineers specialise in the installation and commissioning of chemical injection systems in-line with client’s exact specifications and application of use.

Operating personnel can be trained from us on how to safely operate and calibrate the equipment.

The maintenance, calibration and re-certification of equipment is a safeguard to minimise unexpected breakdowns and downtimes. To ensure that systems are fully functional, we can offer a comprehensive service and maintenance agreement with regular routine maintenance and inspection carried out by trained service engineers on and offshore.