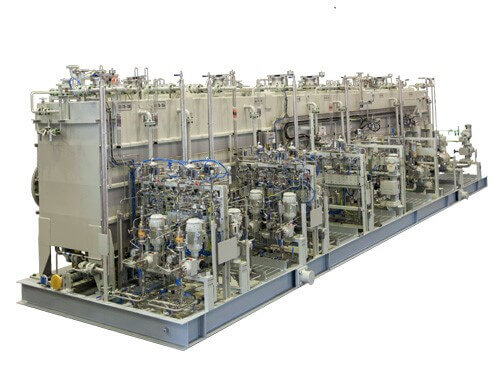

A metering skid is a part of production plant/system that is pre-assembled on a steel structure, engaged to the measurement of gas/liquid products. It can be installed at the onshore or offshore location based on the requirement. Although several process parameters are measured, the primary variable to be measured is the flow rate. Depending on the specific technology and user specifications, the measured flow rate can be a mass flow rate or a volumetric flow rate.

Our metering applications cover both upstream, downstream and transportation operations, including production facilities off-shore and on-shore, transmission and distribution pipelines, refineries, loading and offloading terminals, including import and export and storage facilities, such as tank farms for oil, gas and liquified natural gas. In short, the metering systems can be used for all major type of transportable hydrocarbons- crude oil, natural gas and LNG, condensate, LPG, naphtha, gasoline, diesel, fuel oil etc.

The selection of a specific gas/liquid meter type depends on its application. Therefore, selecting a meter and its auxiliary equipment, as a minimum the following criteria should be considered:

Type of fluid and it’s characteristics.

Amount of foreign matter in fluid(gas) streams.

Flow range and type of flow.

Temperature range and accuracy of temperature compensation.

Maximum operating pressure & maximum permissible differential pressure.

Type of volume registration device.

The required accuracy of the meter.

Type and method of proving required.

Sampling and Analysis Requirement.

Control System requirements.

Installation/Maintenance space requirements etc.