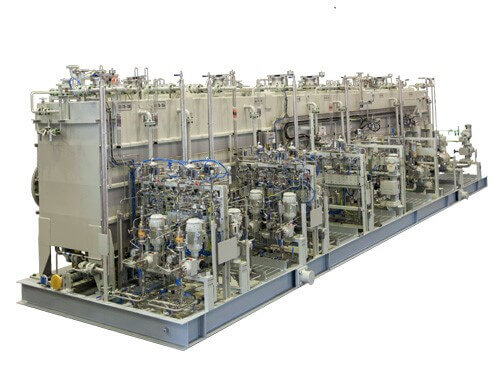

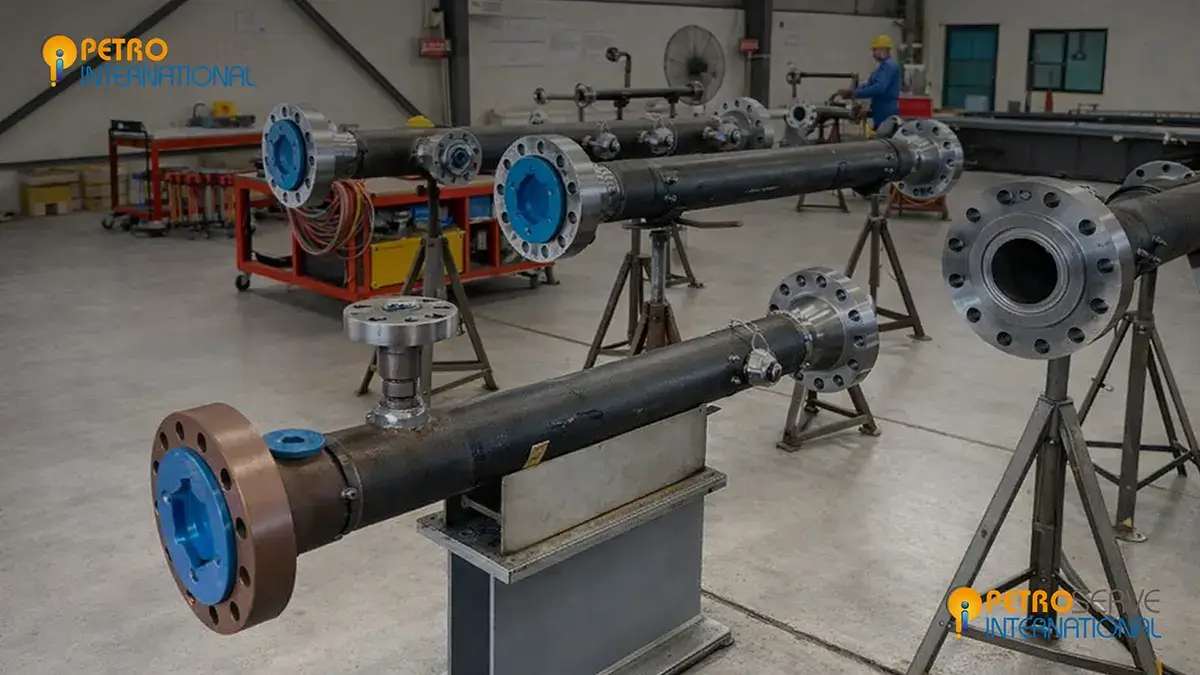

PetroServe International offers comprehensive piping solutions for the oil & gas, petrochemical, water, and industrial sectors, delivering high-quality fabrication, installation, and support services across complex projects. Our experienced team and advanced fabrication facilities ensure precision, efficiency, and compliance with international standards for piping systems of all scales.

Our capabilities cover the entire lifecycle of piping projects, from detailed engineering and material selection to fabrication, inspection, and delivery, ensuring projects are completed safely, on schedule, and to client specifications.

We specialize in the design, fabrication, and supply of various piping systems, including:

Our in-house engineering team utilizes state-of-the-art software such as E3D, SmartPlant 3D, and CAESAR II for stress analysis, routing, and detailed fabrication drawings. All piping systems are designed and fabricated in accordance with international standards and client requirements, including ASME B31.1 / B31.3, ASTM, API, MSS, DIN, and other codes as applicable.

PetroServe International maintains strict quality control and testing protocols, including dimensional inspection, hydrostatic testing, radiographic testing, and coating verification, ensuring durability, safety, and reliable performance in demanding operational environments.