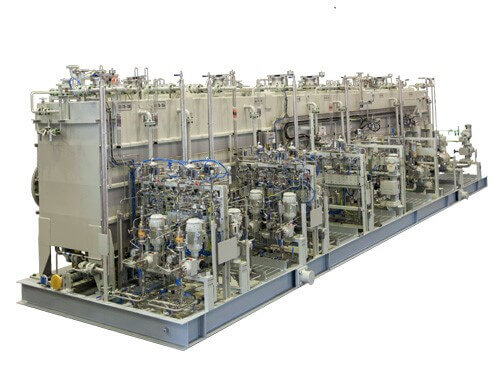

PetroServe International provides end-to-end tank fabrication solutions for the oil & gas, petrochemical, industrial, and infrastructure sectors. Our facilities are equipped to fabricate carbon steel and alloy steel tanks in accordance with international standards and project-specific requirements, ensuring reliability, safety, and long-term performance in demanding operating environments.

With extensive experience in the fabrication of shop-built and field-erected tanks, PetroServe International supports projects across the GCC and international markets. Our skilled workforce, advanced fabrication equipment, and stringent quality control processes enable us to deliver tanks of varying sizes, capacities, and service conditions on schedule and in full compliance with client specifications.